Production process and product flow

With experience in the field of packaging, We create a production process suitable for each product line. Optimization in cost management, quality and time management. Satisfy customers with the most appropriate quality and price schedule.

QUALITY CONTROL PROCESS IN THE PRODUCTION PROCESS

Recognizing the important role of quality in production and business activities of the company. We build a 4-step quality control process. Quality control from source: Quality control from design, pre-production, from our raw material supplier, Quality control during production, Quality control before shipment. Check and monitor the system, check and monitor process compliance, find high-risk points to focus control.

MANUAL DESIGN PROCESS

In order to convey all the customer’s ideas into the packaging design, we make it clear to the customer about the ideas, about the customer’s wishes. Update design skills, knowledge in the field, experience in the industry, coordinate with the technology department in the process of structural prototyping. To meet customer standards. Design information is agreed to be exchanged and checked right from the design stage. Make sure there are no errors in content or images. We are committed to a design team with many years of experience that will satisfy all customers when coming to us.

TECHNOLOGY EQUIPMENT & PRODUCTION CAPACITY

02 CTP CLEANER

Amsky Ausetter T832

- Zinc size: 1130 x 900mm

- Speed: 16 shots/hour

Amsky Ausetter T800+

- Zinc size: 1130 x 900mm

- Speed: 28 shots/hour

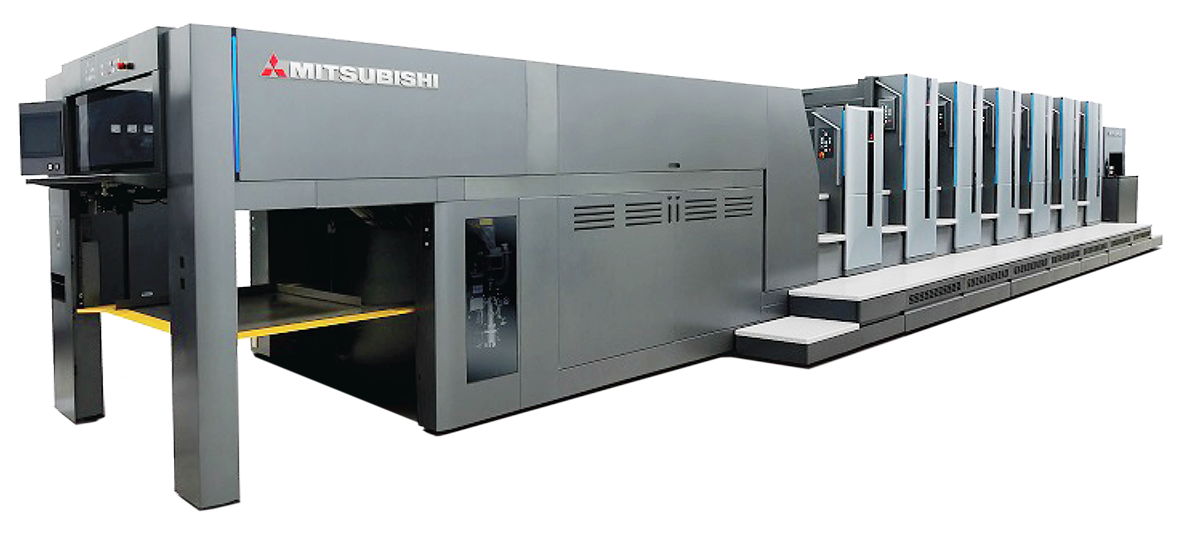

07 offset printers

01 6-color printer + IR coating

- Size : 720 x 1020mm

- Speed: 16,000 sheets/hour

03 5-color printers

- Size : 520 x 720mm

- Speed: 16,000 sheets/hour

01 6-color printer + IR coating

- Size : 520 x 720mm

- Speed: 16,000 sheets/hour

01 4-color printer

- Size : 720 x 1020mm

- Speed: 16,000 sheets/hour

01 2-color printer

- Size : 520 x 720mm

- Speed: 16,000 sheets/hour

04 label printers

01 5-color SEN label printer + 1 die station

- Size : 245 x 250mm

- Speed: 200 jerks/minute

02 5-color SANJO label printer

- Size : 245 x 250mm

- Speed: 220 jerks/minute

01 3-color IWASAKI printer

- Size : 220 x 160mm

- Speed: 220 jerks/minute

01 high speed discharge machine

- Size : 1400mm

- Speed: 300 m/min

02 AEM-1080 automatic die machine

- Size : 780 x 1080mm

- Speed: 7,000 sheets/hour

04 emulsifier (needle)

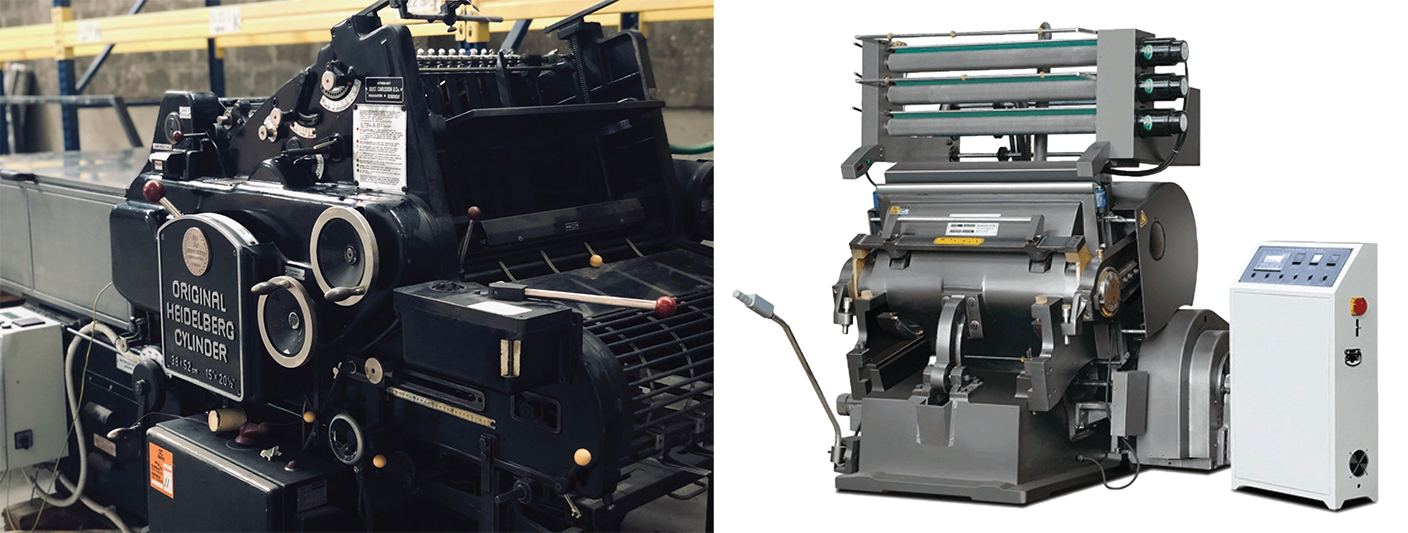

01 automatic heidelberg cylinder emulsifying machine

- Size : 560 x 770mm

- Speed: 2,800 sheets/hour

03 semi-automatic emulsifying machine

- Size : 670 x 930mm

- Speed: 1,200 sheets/hour

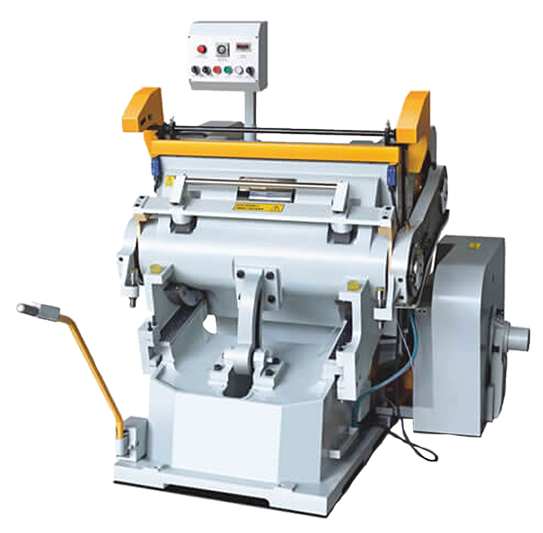

08 semi-automatic die cutting machine

- Size : 670 x 930mm; 800 x 1100mm

- Speed: 1,200 sheets/hour

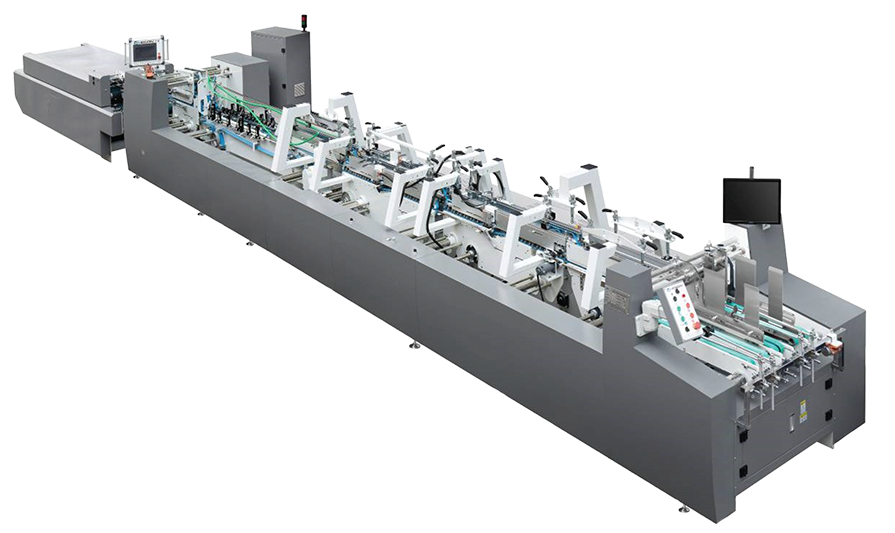

05 automatic box sealing machine

- Size : min 104 x 65mm; max 750 x 400mm

- Speed: 200 m/min

01 CAUNTA G-800 window sealer

- Size : min 120 x 97mm; max 800 x 550mm

- Speed: 10,000 products/hour

04 hard box pass

02 slitting machine

- Size : min 120 x 97mm; max 800 x 550mm

- Speed: 10,000 products/hour

01 QFM-600B automatic cardboard machine

- Size : min 100 x 230mm; max 600 x 1030mm

- Speed: 10,000 products/hour

01 GR-1200Z automatic box assembly machine

- Size : min 70 x 70 x 15mm; max 480 x 480 x 120mm

- Speed: 28 products/minute

05 hard box indent machine

- Size : min 60 x 60 x 50mm; max 650 x 450 x 150mm

- Speed: 1,000 products/hour