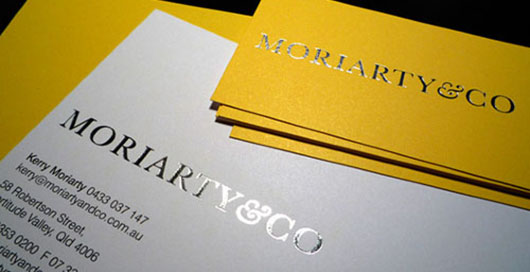

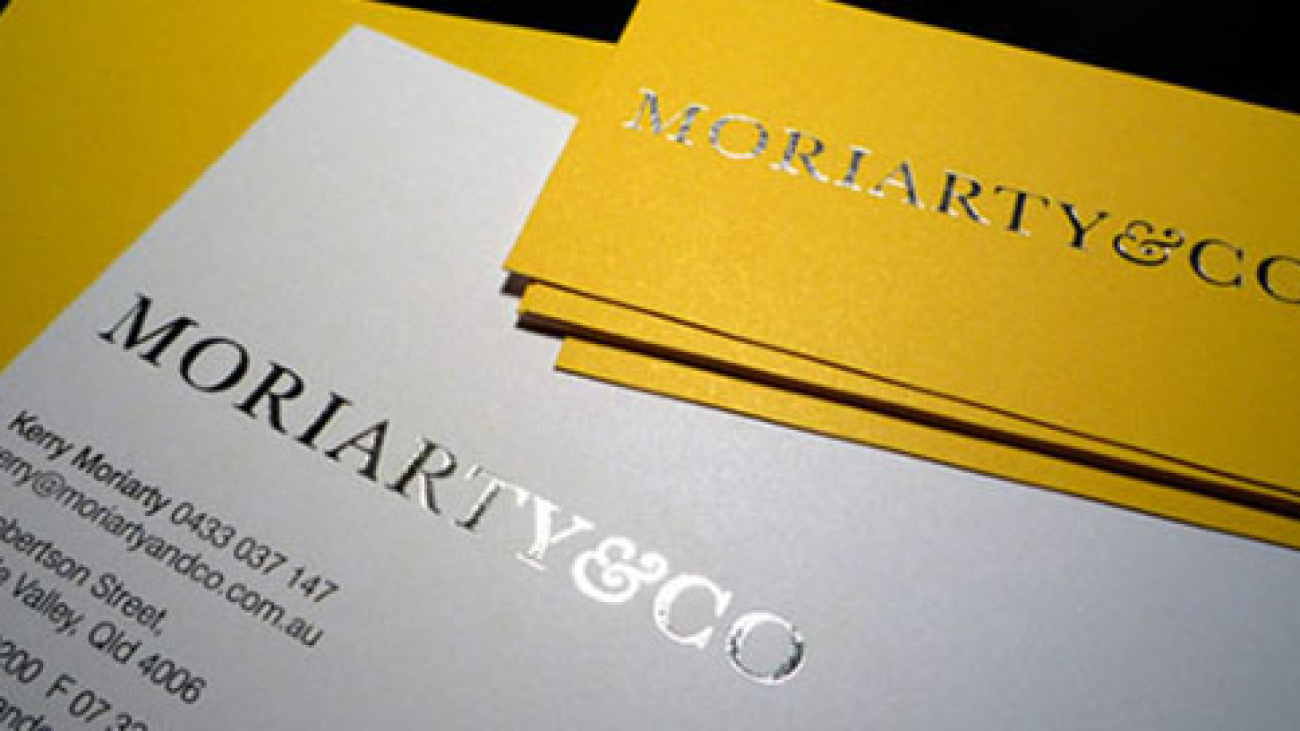

To create accents or highlight logos, brand names, slogans, banners, etc. on paper packaging publications, we often use needle pressing technique. Because the laminated details are glossy and sharp, the surface easily catches the light, making the paper packaging products sparkle and delicate.

Why should you choose metallurgy?

Embossing is a technique of gluing gold, silver, etc. to the text and images on paper or leather.

There are two types of molds used in the process of pressing paper packaging: copper and zinc molds. Although zinc molds are widely used, the cost is cheap, but the durability is less than that of copper molds. Moreover, using copper mold brings more precision and sharpness to the product.

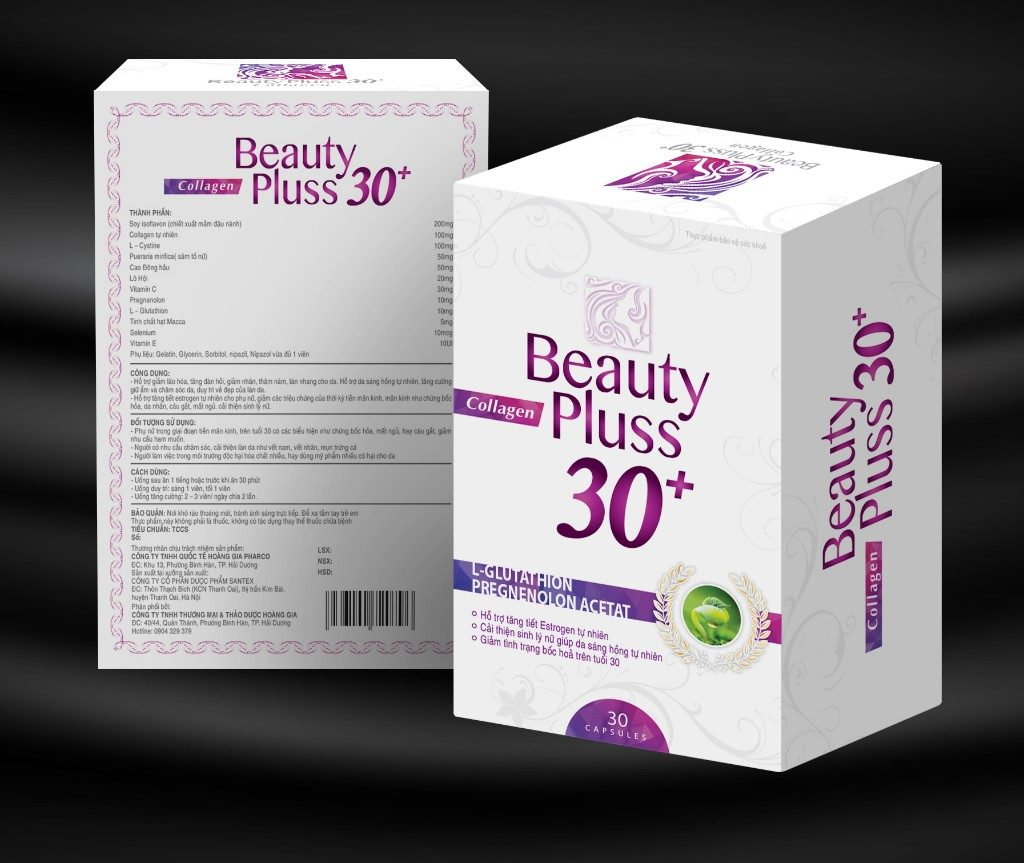

If we pay attention, we will see namecards, bags, paper boxes … of high-end product lines such as perfumes, cosmetics … often using needle pressing technique. In this way, the paper packaging will become more luxurious, making consumers feel the class and sophistication of the product.

In addition, the lamination helps to print the paper packaging without color smearing, creating sharp visual effects, the light-sensitive laminated surface easily attracts attention and makes a good impression.

Needle pressing – Meticulous, careful in every detail

The technique of metallization is commonly used in publications such as: paper boxes, namecards, wedding cards, vouchers, menus, catalogs, paper bags… Depending on the type of product, the color of metallization is as rich and diverse as gold emulsion. , silver or blue, red.

When metallizing a design on paper box products, printing technicians must create an aluminum or copper mold with engraved logos, words and images similar to the design. In which, the lines must be inverted negative table.

Next, the aluminum and copper molds are positioned or glued to the correct positions on the thermal board. Depending on the type of foil, the temperature of the thermal pad ranges from 70 to 100 degrees Celsius. Then, apply pressure to the surface of the paper for a short period of time from a few seconds to a few minutes.

Needle pressing – Don’t worry about being out of date

In terms of cost, in general, when pressing or embossing paper packaging, the cost is also relatively the same. Compared with needle pressing, the emulsion printing technique has a young age, but the printing time is faster and more convenient because there is no need to make a mold or use a heat press machine.

However, needle pressing will help the details on the package to be more concave and deeper, the image quality is also sharper and more perfect than the emulsion printing. Therefore, if the finished paper packaging product requires sophistication and elegance, Ha An advises you to use the needle pressing technique to create class and professionalism in your publications.

Add a Comment