1. What is the paper weight for different types of paper packaging?

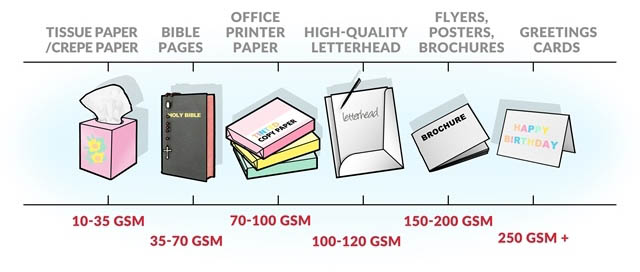

Paper weight is the weight of one sheet of paper per square meter of paper (in gms or g/m2). For example, you want to make packaging using Bristol paper weighing 300gms. That is, a piece of Bristol paper with an area of 1 square meter weighs 300 grams. Thus, the larger the paper, the thicker and harder it is. Conversely, the smaller the quantity, the thinner the paper.

2. Why should paper quantification?

Why do textbooks often use golden Ford paper 70 – 90g/m2, high fashion magazines use Couche paper 90 – 300g/m2, while wedding invitations are made from Bristol paper measuring 230 – 350g/m2…. The difference in the amount of paper used is due to the following reasons:

Firstly, the purpose and role of different packaging printing products should be selected according to the appropriate paper material. For example, paper packaging used to store, transport products, transport goods, etc., needs more thickness and durability than printed publications used to store information, introduce images or promote brands. . Paper weight determines the thickness, hardness, strength, compression, impact resistance … of the finished product.

Second, customer needs in terms of implementation costs, different usage time. Quantifying the right type of paper for these factors not only satisfies the needs of customers but also creates the best paper packaging.

Finally, the paper quantity affects the entire operation of the printer. In case the printed paper is too thin or too thick, it will significantly affect the printer, possibly causing paper jams or damage to internal components. Besides, in order to have an offset printing paper box with sharp and delicate images, it is very important to choose a paper capable of “eating ink” and “catching color”.

3. How is paper weight tested?

One of the international quality accreditation certificates is reliable assessment such as SGS (Switzerland), ITS (USA), BVQI (UK), DNV (Norway)… Criteria as the basis for assessment in accordance with ISO 9001:2000 – A recognized standard in Vietnam and most other countries in the world.

In fact, paper manufacturers all record quantitative parameters, so you can identify them easily. However, the quantitative indicators often have errors due to objective factors such as weather, humidity, air temperature, or subjective factors such as production techniques (matte/glossy lamination, etc.).

To get the desired printing and packaging products, you should be careful in choosing the right paper size. For support and advice on information about paper packaging, please contact Ha An via:

Email: business@inhaan.vn

Tel: 024 625 36492

Add a Comment